BMS-III

Brake Monitoring System

BMS-III (Brake Monitoring System 3) is the third generation of BMS researched by adopting the latest state of the art HECS platform created by our main shareholder company and based on discussions and requests from customers.

It aims to fulfil the status monitoring of brakes in coordination with host computers, make a diagnosis and analysis of the brake faults and store the fault data, further provide the upgrading and optimizing of brakes with necessary basis.

BMS-III is divided into two versions: basic and advanced.

Basic version

In-service Inspection

Detecting the status informations and fault informations of the brake

in real time and transmit it to the host to ensure its safe service.

Contact force sensor

Pad wear and and pad temperature sensor

Reserve stroke sensor

Advanced version

Storage and Display of Fault Data

The data before and after faults occurring are stored on BMS-III to know the time of the faults, the state of the brake before and after the faults. The information can be checked by the software HECS-ST of PC, and is convenient to analyze faults in the field.

Assessment of remaining lifetime

By recording and analyzing the brake normal braking times, emergency braking times and factory information,

the remaining life of the brake is evaluated, and the decision-making is made for the later service, transformation or retrofit of the brake.

| Inspection of release/ close times |

Display the release/close times of brakes; Distinguish the release/close times of emergency brake and normal brake; After applying emergent braking every time, report “Brake counter exceed limit,replace unit!”. |

|---|---|

| Delivery information | Record the delivery time and calculate current accumulated working time of brake. |

BMS-III

Function

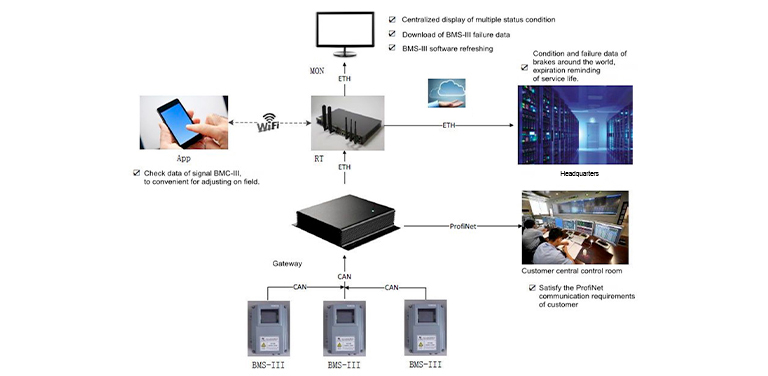

Centralized display (Optional)

Because of the inconvenience to view the state of the brake on the spot which is not easy to check,

the data of multiple BMS-III are displayed on a single display screen –> convenient for field personnel.

Hand-held Diagnosis Instrument (Optional)

BMS-III can be configured with a hand-held diagnostic instrument connected via the network.

ProfiNet, with cloud technology (Optional)

Multiple BMS-III are connected to the Profinet/CAN gateway through CAN bus, thus connecting to the ProfiNET network, improving the utilization of the ProfiNET bus, reducing nodes, and reducing costs. The ProfiNET/CAN gateway can be used as a ETH/CAN gateway to access the monitor to view data centrally.

BMS-III

Brake Upgrades

Improvement

Maintenance without a monitoring system is a challenge, as it is necessary to regularly inspect brake lining wear,

eccentric wear and brake compensation.

Restricted access to the brake (e.g. on the trolley) or bad weather conditions make it difficult for the service person in charge

to carry out the inspection and it can easily be missed.

In addition, brake performance is reduced by wear as the system is operated for longer periods of time and cannot be measured visually.

In order to obtain the brake data accurately, reduce the workload of field staff and find the brake fault in time, BMS-III can be installed on the brake to solve the above problems.

Required information for upgrade

Drawings, process documents, bill of material, etc.

Unsere BroschüreN

ABS

Storm protection equipment

Rope drum coupling

No downloads found